How 3D Printing is Revolutionizing Inflatable Design

The world of inflatables is evolving rapidly, and one of the key technologies driving this change is 3D printing. From creating customized designs to improving the durability and functionality of inflatables, 3D printing is revolutionizing the way inflatable structures are produced. For businesses in Canberra involved in event planning, inflatable rentals, and amusement park operations, understanding the impact of 3D printing on inflatable design can offer exciting opportunities for growth and innovation.

1. Customization and Creativity

One of the most significant advantages of 3D printing in inflatable design is the ability to create highly customized structures. Traditional inflatable manufacturing methods often require molds or patterns, which can be expensive and limit creativity. With 3D printing, designers can create unique and intricate shapes that would be difficult or impossible to achieve using conventional methods. This opens the door to more creative and eye-catching inflatables, such as custom-made bounce houses, obstacle courses, or promotional inflatables tailored to specific events or branding needs.

For businesses in Canberra, this means you can offer clients one-of-a-kind inflatables that stand out at events, attracting more attention and delivering a memorable experience. From company logos to themed inflatables that match an event’s aesthetic, 3D printing allows for limitless creativity in design.

2. Improved Structural Integrity and Durability

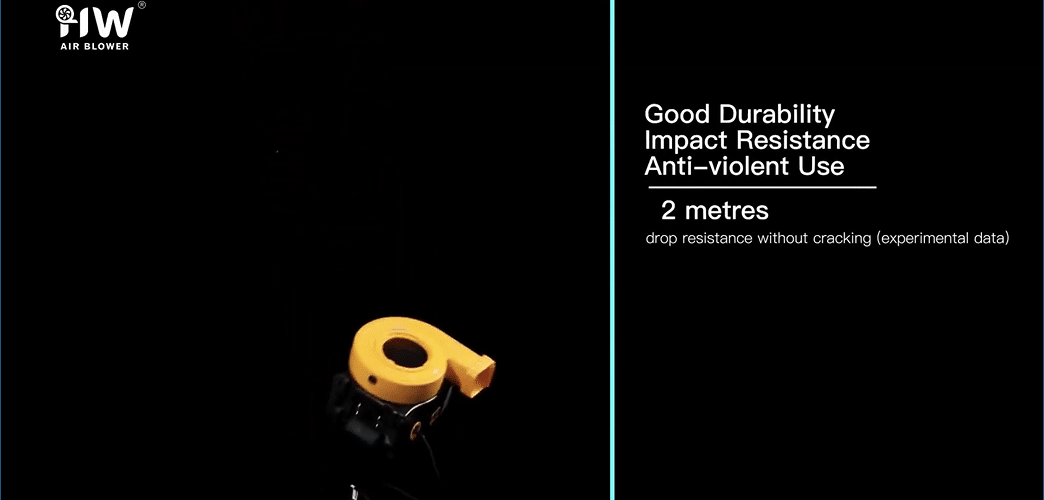

Another area where 3D printing is making a significant impact is in the structural integrity and durability of inflatables. 3D printing allows for precise control over material distribution, which can be used to reinforce areas of inflatables that experience the most stress, such as seams, anchor points, and pressure zones. By optimizing the design and material usage, 3D-printed components can enhance the overall strength and longevity of inflatable structures.

This is particularly beneficial for commercial inflatables that undergo frequent use and need to withstand heavy loads and rough conditions. Event planners and rental businesses in Canberra can benefit from longer-lasting inflatables that require fewer repairs and maintenance, ultimately reducing operational costs and improving profitability.

3. Faster Prototyping and Production

3D printing is also revolutionizing the speed at which new inflatable designs can be prototyped and brought to market. In the past, creating prototypes of inflatables required lengthy development times, often involving hand-crafted models and multiple iterations before reaching the final design. With 3D printing, designers can quickly produce accurate prototypes to test for functionality, fit, and stability before mass production. This accelerates the innovation process, allowing companies to bring new, cutting-edge inflatable products to the market faster than ever before.

For Canberra businesses looking to stay ahead of trends and offer the latest in inflatable entertainment, the faster production timeline provided by 3D printing gives a competitive edge. This is particularly useful for event-based businesses that need to adapt to seasonal trends or cater to unique, last-minute client requests.

4. Sustainability in Inflatable Manufacturing

Sustainability is becoming an increasingly important consideration across industries, and 3D printing is contributing to more environmentally friendly manufacturing processes in the inflatable industry. 3D printing allows for precise control over material usage, reducing waste and ensuring that only the necessary amount of material is used for each part. Additionally, many 3D printing materials are recyclable or made from renewable sources, further reducing the environmental impact of production.

For businesses that prioritize sustainability, offering eco-friendly inflatables produced through 3D printing can be an attractive selling point. This aligns with the growing demand for sustainable practices in event planning and entertainment, giving Canberra businesses an opportunity to appeal to environmentally conscious clients.

Conclusion

3D printing is transforming the inflatable industry by enabling greater customization, enhancing durability, speeding up prototyping and production, and contributing to more sustainable manufacturing processes. For businesses in Canberra, embracing 3D printing technology offers a wealth of opportunities to provide unique, high-quality inflatables that meet the evolving demands of customers. As this technology continues to develop, the possibilities for innovation in inflatable design are endless, making it an exciting time to be part of this industry.